Design for Manufacturing: Best Practices from Pizzuti Design

Understanding Design for Manufacturing

Design for Manufacturing (DFM) is a crucial concept that bridges the gap between design and production, ensuring that a product is easy to manufacture with high quality and at a low cost. At Pizzuti Design, we emphasize the importance of integrating DFM principles early in the product development process to streamline production and optimize resources.

By focusing on DFM, companies can reduce production time, minimize costs, and improve product quality. The key is to consider manufacturing constraints and capabilities during the design phase, allowing for a smoother transition from prototype to production.

Incorporating DFM Principles

At Pizzuti Design, we believe that the integration of DFM principles should begin at the very start of the design process. This proactive approach helps in identifying potential issues before they become costly problems. Here are some best practices to consider:

- Simplify Designs: A simpler design not only speeds up manufacturing but also reduces errors and material waste.

- Standardize Components: Using standard components can lower costs and reduce inventory complexities.

By simplifying and standardizing, designers can make significant strides in efficiency, ultimately benefiting the entire production chain.

Collaboration Across Teams

One of the pillars of effective DFM is fostering collaboration between designers, engineers, and manufacturers. At Pizzuti Design, we encourage cross-functional teams to work together from the outset. This collaboration ensures that everyone is on the same page regarding design objectives and manufacturing capabilities.

Open communication channels allow for real-time feedback and adjustments, reducing the risk of misalignments that could lead to costly redesigns or production delays.

Leveraging Technology in DFM

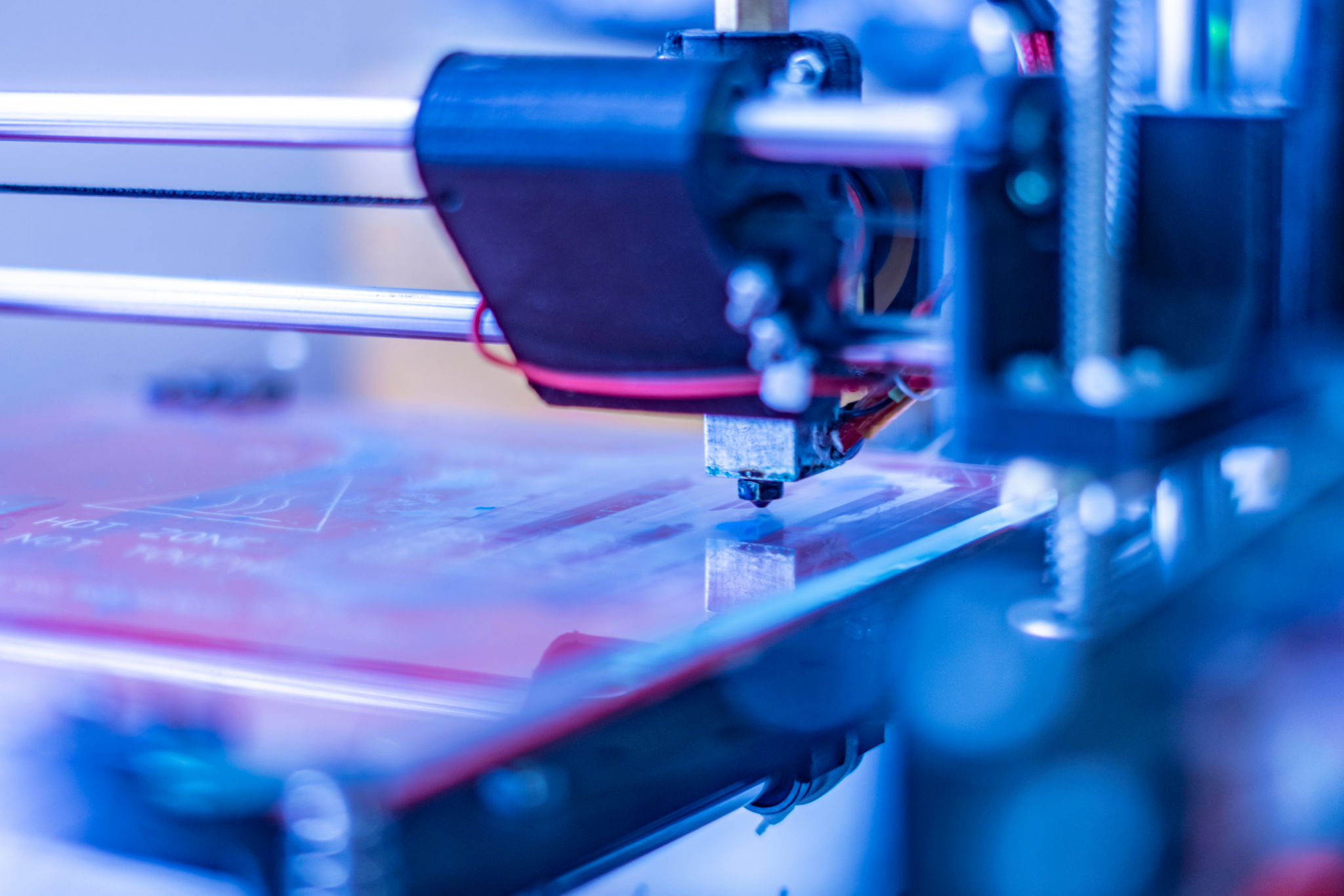

Technology plays an instrumental role in enhancing DFM practices. Advanced software tools can simulate manufacturing processes, allowing designers to visualize potential issues before they arise. Pizzuti Design leverages these tools to refine designs and optimize manufacturing workflows.

Moreover, technologies such as 3D printing provide rapid prototyping capabilities, enabling quick iterations and validation of design concepts. This agility helps in fine-tuning product designs to meet both aesthetic and functional requirements efficiently.

Continuous Improvement

The journey of DFM is one of continuous improvement. At Pizzuti Design, we advocate for a culture of ongoing learning and adaptation. By regularly reviewing manufacturing processes and incorporating feedback, companies can identify areas for enhancement and implement changes swiftly.

This iterative process not only drives innovation but also ensures that products remain competitive in an ever-evolving market landscape.

The Impact of DFM on Sustainability

Sustainability is another critical aspect where DFM can make a significant impact. By designing products with sustainability in mind, manufacturers can reduce material waste, minimize energy consumption, and support environmentally friendly practices.

Pizzuti Design places a strong emphasis on sustainable design solutions, recognizing that mindful manufacturing practices contribute to both business success and environmental stewardship.

Conclusion

Design for Manufacturing is an indispensable strategy for companies aiming to produce high-quality products efficiently and cost-effectively. By embracing DFM principles, fostering collaboration, leveraging technology, and committing to continuous improvement, businesses can achieve substantial gains in productivity and sustainability.

At Pizzuti Design, we are committed to helping our clients navigate the complexities of DFM, ensuring their products meet the highest standards of quality and performance. Implementing these best practices can unlock new levels of success and innovation in the manufacturing domain.