Design for Manufacturing: Key Considerations for Effective Product Development

Understanding Design for Manufacturing

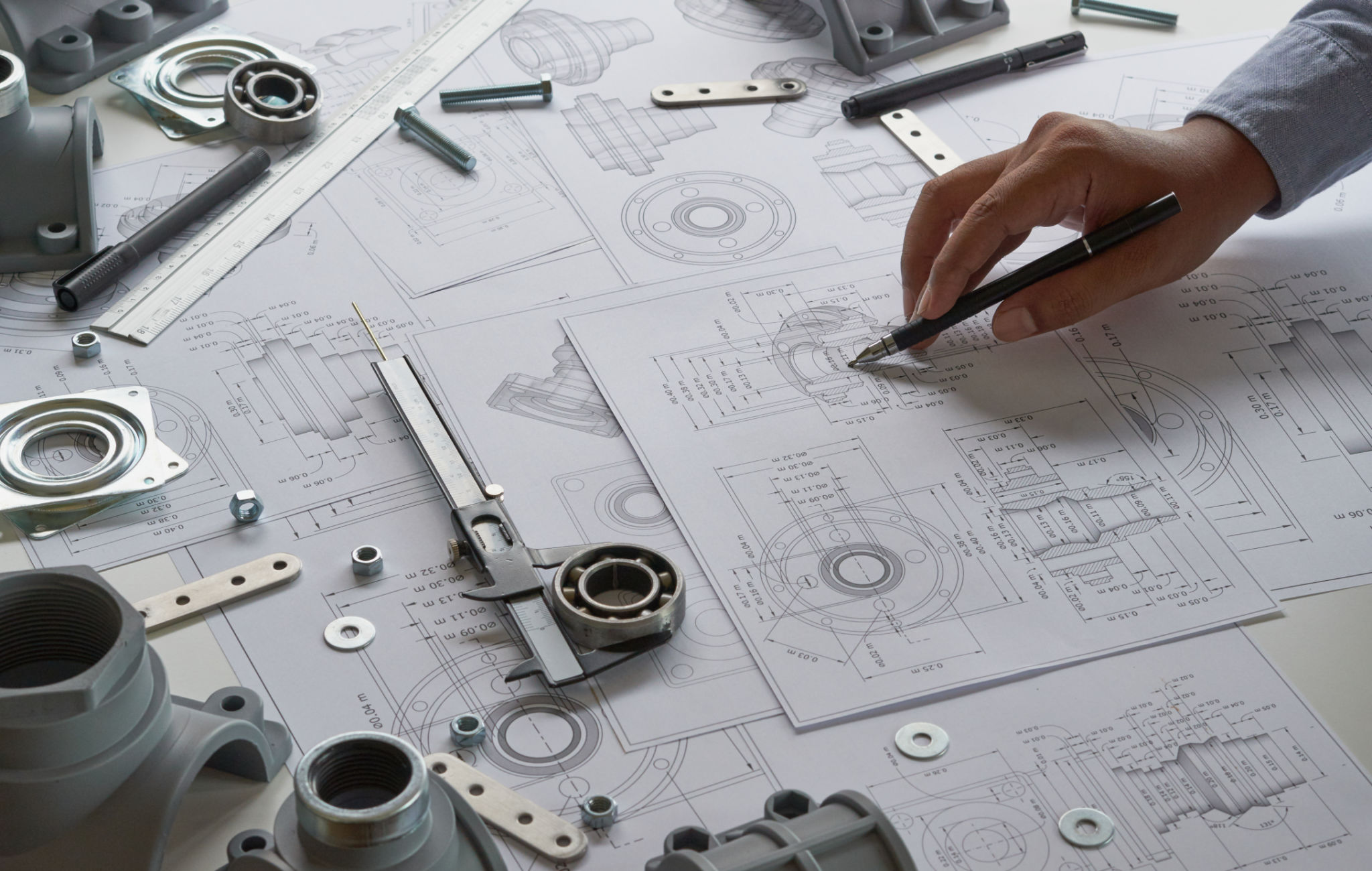

Design for Manufacturing (DFM) is a critical aspect of product development that involves designing products with manufacturing in mind. By considering the manufacturing processes early in the design stage, companies can reduce production costs, improve quality, and accelerate time to market. This approach ensures that products are not only innovative but also practical to produce.

DFM requires collaboration between designers and engineers to create products that are easy to manufacture. This collaboration can lead to more efficient use of materials, streamlined assembly processes, and reduced waste. By prioritizing manufacturing considerations from the outset, businesses can avoid costly redesigns and delays.

Key Considerations in DFM

Material Selection

Selecting the right materials is a cornerstone of effective DFM. The choice of material impacts not only the product's performance but also its manufacturability. Designers must consider factors such as material availability, cost, and compatibility with manufacturing processes. Using materials that are readily available and easy to work with can significantly reduce production time and costs.

Standardization

Standardization involves using common components and processes across different products. This approach can simplify manufacturing by reducing the need for unique parts and specialized equipment. By designing products with standardization in mind, companies can achieve economies of scale, streamline inventory management, and enhance production efficiency.

Simplifying Product Designs

Simplifying product designs is another important strategy in DFM. Complex designs often require more intricate manufacturing processes, which can lead to higher costs and longer production times. By minimizing the number of components and using straightforward assembly techniques, companies can make products easier and cheaper to produce.

A simplified design not only benefits the manufacturer but also enhances product reliability. Fewer parts mean fewer opportunities for failure, which can improve the overall quality and durability of the product. This approach also facilitates easier maintenance and repairs, contributing to a better customer experience.

Ensuring Quality Control

Incorporating Quality Checks

Quality control is an integral part of DFM to ensure that products meet the required standards consistently. Incorporating quality checks into the design phase can help identify potential issues before they become costly problems. Automated testing and inspection processes can be integrated into the production line to maintain high quality without significantly increasing costs.

Feedback Loops

Establishing feedback loops between the manufacturing team and the design team is crucial for continuous improvement. By analyzing production data and customer feedback, companies can make informed adjustments to their designs, enhancing manufacturability and product performance over time. This iterative process helps in refining products while keeping them aligned with market needs.